Contents

- 1 Introduction

- 2 Understanding the Modern Supply Chain

- 3 What is Artificial Intelligence (AI) in Supply Chain?

- 4 Key Areas of AI-Driven Supply Chain Improvement

- 5 Practical Steps to Use AI in Your Supply Chain

- 6 The Tangible Benefits of AI in Supply Chains

- 7 Challenges and Thoughts for AI Use

- 8 The Future of Supply Chain with AI

- 9 Conclusion

Introduction

The world economy grows more complex. Old supply chain methods struggle. They cannot meet market needs. They face unexpected problems. Customers expect more every day.

This article shows how Artificial Intelligence (AI) and Machine Learning (ML) change supply chains. They shift operations from reactive to predictive. They make systems proactive. AI technologies do more than improve speed. They reshape how goods and services move worldwide.

Why This Matters

Today’s business world changes fast. Small online shops and large companies must improve supply chains. Why does this matter? This means more than cutting costs. It means building strength. It means acting fast. It means gaining an advantage over rivals.

AI processes large data sets. It finds hidden patterns. AI automates hard decisions. It predicts future trends. This happens with great exactness.

This matters greatly. Companies reduce waste. They improve delivery times. They make customers happier. They lessen risks. They adapt quickly to market changes. This affects profit and long-term business health. Supply chain managers, logistics workers, operations directors, and business leaders will find this information useful.

What This Article Covers

This article covers:

- Modern supply chain problems that need AI.

- What AI is and its parts in supply chains.

- How AI helps different supply chain jobs. This includes forecasting, inventory, logistics, and risk management.

- How to put AI solutions into your business.

- Benefits businesses get from AI in their supply chain.

- Challenges when using AI.

- The future of AI in supply chains.

Understanding the Modern Supply Chain

Today’s global supply chain is a wide, complex network. It is very different from past simple models. It handles raw material sourcing, making goods, storing them, moving them, and final delivery. This complexity brings weak points.

Evolving Challenges and Complexities

Businesses face many problems:

- Globalization means networks span continents. This makes control and oversight hard.

- Uncertainty is common. World events, natural disasters, trade issues, and global health crises can cause sudden, big problems. This shows long supply lines are weak.

- Customers want faster delivery. They want more clear information. They want personal service. They often want good environmental practices.

- Modern supply chains create too much data. This data comes from many sources. Getting useful facts from this data stays hard.

- Pressure grows to cut carbon use. Businesses must reduce waste. They must make sure sourcing is ethical. This adds more layers of trouble.

- Finding and keeping skilled workers in logistics and storage is an ongoing problem.

The Need for Agility and Strength

The world changes fast. Businesses must adapt quickly. They must recover from problems. Old ways of planning do not work. Human problem-solving is not enough. AI helps. It provides the needed power. It handles complex systems. AI changes how companies manage supply chains. It moves them to top performance and quick adaptation.

What is Artificial Intelligence (AI) in Supply Chain?

AI simulates human thinking processes. Machines do this, especially computer systems. These processes include learning, thinking, solving problems, sensing, and making choices. In supply chains, AI automates tasks. It reads large data sets. It predicts results. It runs complex operations. It does this without direct programming for every step.

Defining AI and Its Parts

AI has several key parts for supply chains:

- Machine Learning (ML): ML is the most common AI form in supply chains. ML allows systems to learn from data. It finds patterns and makes choices with little human help. For example, it predicts demand or finds errors in quality checks.

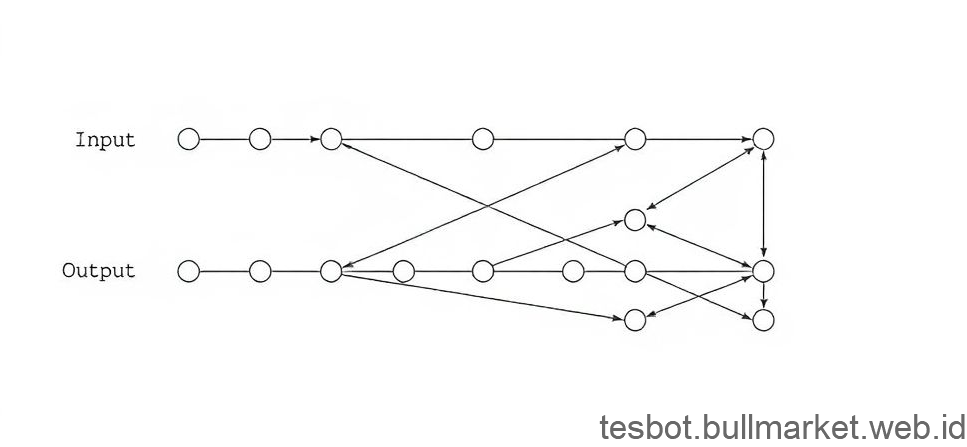

- Deep Learning (DL): DL is part of ML. It uses many network layers to learn from much data. DL works well for hard tasks. These tasks include image recognition or understanding human language.

- Natural Language Processing (NLP): NLP helps computers understand human language. It helps them write it. In supply chains, NLP reads supplier papers. It reads customer comments. It reads market news for risk review.

- Computer Vision (CV): CV lets computers see. They interpret pictures or videos. This helps with automatic quality checks. It helps with warehouse inventory checks. It helps with security.

- Reinforcement Learning (RL): RL is an AI type. Here, a system learns to make choices. It acts in an environment. It gets rewards or penalties. This works for changing routes. It works for complex robot movements in warehouses.

How AI Changes Old Ways

AI adds a smart layer to supply chain work. It makes operations proactive, not reactive. It makes them data-driven and automated. AI moves past simple rules. It uses complex models that learn and get better. This helps make more exact decisions. It speeds up work. It reduces human error a lot.

Key Areas of AI-Driven Supply Chain Improvement

AI helps nearly every supply chain part. These are the strongest uses.

Demand Forecasting and Planning

Exact demand prediction builds a good supply chain. Old ways often cannot handle market changes or outside forces. AI, especially Machine Learning and Deep Learning, works very well here.

- Predictive Analytics: ML models read past sales data. They look at special events, economic signs, weather, and social media trends. They check rival actions. This predicts future demand with great exactness.

- Real-time Adjustments: AI systems learn from new data all the time. This allows quick changes to predictions. They react to events as they happen. They do not use old yearly or quarterly plans.

- Scenario Planning: AI can show many ‘what if’ situations. This helps businesses know how choices affect demand. They can then plan.

Example: A clothing company uses a neural network, a kind of deep learning model. It looks at past sales. It checks local festival dates. It uses news about raw materials. It sees social media talk about a product. This helps predict demand for seasonal clothing. It is 15% more exact than old ways.

Inventory Management

Having the right amount of goods is hard. Too much stock uses up money and space. Too little stock means sales are missed. AI finds the best balance for this.

- Dynamic Reorder Points: AI changes order points and amounts. It bases this on live demand changes, delivery times, supplier results, and storage costs.

- Old Stock Identification: ML models find goods that sell slowly. They find old goods before problems grow. They suggest ways to clear or reuse items.

- Many-Place Stock Check: AI can check goods in many places. This means warehouses, distribution centers, and stores. It checks them all at once. This makes sure goods are where they are needed.

Example: A factory uses a learning system. It watches stock levels. It checks new orders, production plans, and supplier delivery times. It learns when and how much raw material to order. This cuts stock costs by 10%. It keeps services at the same level.

Logistics and Transportation Improvement

Transport costs are often the biggest part of a supply chain. AI makes transport much better.

- Route Planning: AI systems read much data. They check traffic, road closures, weather, delivery times, vehicle space, and driver numbers. They find the quickest routes right away. This saves fuel. It cuts travel time. It makes deliveries more sure.

- Truck Group Management: AI improves truck care. It uses data from truck sensors. It predicts when trucks need service. It helps assign vehicles well. It tracks vehicles live.

- Load Planning: AI finds the best way to load trucks or containers. This uses space well. It cuts down on trips.

Example: A logistics business uses an AI system. It links GPS data, live traffic news, and weather facts. The system changes truck routes live. It does this even during a trip. It avoids traffic or bad weather. This cuts late deliveries by 20%.

Warehouse Operations and Automation

Warehouses get more automated and smart with AI.

- Robots and Automation: AI runs robots. These robots pick, pack, and sort items. Robotic arms do the same tasks many times. This raises output and exactness greatly.

- Layout Planning: AI checks how products move. It checks how orders get filled. It suggests the best warehouse layouts. It suggests good ways to put items and picking paths.

- Machine Care Prediction: Machine Learning reads data from warehouse machines. This includes belts and forklifts. It predicts when machines might break. This allows early repairs. It cuts down on time machines are not working.

- Computer Vision for Quality and Stock: Cameras with AI quickly check incoming goods for damage. They check outgoing goods. They can even count stock by themselves.

Example: An online store uses AI robots. These robots learn the fastest ways to get items. A camera system on drones scans shelves. It updates stock counts by itself. It finds misplaced items with 99% correct results.

Supplier Relationship Management

Good supplier management keeps a supply chain steady. AI offers strong tools here.

- Supplier Risk Check: AI reads many outside sources. These include news, money reports, social media, and world events. It checks internal results. It uses this to check supplier truth. It finds possible risks early. These risks include money issues or moral concerns. This happens before problems grow.

- Performance Check: AI checks supplier results all the time. It checks against key goals. It tells managers about errors.

- Paper Check: NLP quickly reads supplier papers. It pulls out key facts. It helps find chances for better talks. It makes sure rules are met.

Example: A factory uses an NLP AI system. It reads thousands of news stories. It checks money reports and rule changes every day. It shows possible risks for its suppliers. These risks include worker disputes, material cuts from world events, or lower credit scores. This helps the factory get new suppliers early or change orders.

Quality Control and Risk Management

AI helps control quality and risks, not just with suppliers.

- Quality Prediction: ML models read production data. They check sensor readings and outside facts. They predict likely errors or quality problems before they happen. This helps with early action.

- Error Finding: AI finds strange data patterns very well. These patterns can show fraud, bad work, or security issues in the supply chain.

- Full View: AI links data from many systems in the supply chain. This gives a complete, live view. This view helps find and cut risks fast.

Example: A food company uses AI sensors and cameras on its production line. The AI reads live pictures and data. It finds tiny flaws in products or packing. This keeps quality steady. It meets health rules. This greatly cuts product recalls.

Practical Steps to Use AI in Your Supply Chain

Putting AI in place is a process, not a quick task. These are the main steps:

Define Clear Goals and Measures

Before you start, state your goals clearly. Say what success means. Do you want to cut costs? Make deliveries faster? Make predictions more exact? Or lower risks? Set clear ways to measure your progress.

Example: Cut stock storage costs by 15% in 18 months with AI demand prediction.

Data Collection and Preparation

AI models are good only with good data. This is the most important step.

- Find Data Sources: Use stock records, sales data, and delivery data like GPS. Use supplier results, outside market data like economy signs and weather. Use social media trends.

- Check Data Quality: Data must be clean, steady, exact, and useful. This often means cleaning data. It means linking data from many systems. It means setting up data well.

- Data Storage: Build strong systems to hold and manage much data.

Choose the Right AI Tools and Technologies

Many AI tools exist.

- Ready-made Tools: Many sellers offer special AI software for supply chain tasks. These include demand prediction tools or delivery route tools. They can be quicker to set up.

- Custom Building: Sometimes you need to build custom AI models. This is for special problems or business gains. This often needs data scientists and ML engineers.

- Cloud Systems: Use cloud providers like AWS, Azure, Google Cloud. They give AI systems that can grow. They offer ready ML services.

Start Small and Grow

Do not try to put AI everywhere at once.

- Test Projects: Start with a small, focused test. For example, predict demand for one product line. Or plan routes for one area.

- Step-by-step Approach: Learn from your test. Make the models better. Show how it helps. Then slowly expand to other areas. This cuts risk. It builds trust inside the company.

Grow a Culture of AI Use

Technology alone is not enough. People must accept it.

- Leadership Support: Get support from leaders and all affected groups.

- Training: Teach workers how to use AI tools. Help them read results. Help them understand new work methods. Speak to worries about job loss. Show AI helps people do their jobs better.

- Change Management: Manage the shift actively. Share benefits. Deal with worries.

Continuous Monitoring and Improvement

AI models change.

- Performance Check: Check your AI models’ performance all the time. Use your set measures.

- Model Updates: Markets change. New data comes. AI models need updates to stay exact and useful.

- Feedback: Get feedback from work teams. This helps make AI inputs and outputs better.

The Tangible Benefits of AI in Supply Chains

Using AI well gives big benefits. These go beyond just faster work.

Better Speed and Cost Cuts

- Automating Repeat Tasks: Frees people for more important work.

- Better Resource Use: Vehicles, warehouse space, and workers are used better.

- Less Waste: Lower stock costs, less spoilage, and fewer rushed shipments due to better planning.

- Fuel Savings: From smart route planning.

More Exact Results and Fewer Errors

- Exact Predictions: Leads to better stock management and production plans.

- Fewer Manual Errors: Automation cuts human errors in data entry and choices.

- Better Quality Control: Finds problems early.

More Strength and Quickness When Problems Hit

- Early Warning Systems: AI can find problems early. These include bad weather, port delays, or supplier issues. This allows early crisis planning.

- Fast Re-routing: AI can change plans fast. It reacts to unexpected events. This keeps work going.

- Scenario Modeling: The ability to quickly check different reactions to problems.

Better Customer Satisfaction

- Faster Deliveries: Better delivery and stock control leads to faster, more reliable deliveries.

- Better Product Availability: Fewer times goods are out of stock.

- Personalized Experiences: AI allows more tailored delivery choices and talk.

Finding New Business Chances

- Data Facts: AI can find new market chances. It can find new customer groups. It can find new product needs. These were once hidden.

- Rival Advantage: Companies using AI can beat rivals. They have faster, cheaper, and more reactive supply chains.

- New Service Offers: Prediction skills can lead to early customer help. Or they can lead to maintenance services.

Below is a table summarizing some key AI uses in the supply chain and their main benefits:

| AI Use Area | Key AI Technologies Involved | Primary Benefits |

|---|---|---|

| Demand Prediction | Machine Learning (Regression, Time Series Analysis), Deep Learning (Neural Networks) | More exact predictions. Less goods out of stock or too much stock. Better production plans. |

| Inventory Management | Machine Learning, Reinforcement Learning | Lower storage costs. Very little waste. Good stock levels in all places. Better money flow. |

| Logistics & Route Planning | Reinforcement Learning, Optimization Algorithms, Real-time Data Analytics | Less fuel cost. Faster deliveries. Lower carbon output. More on-time deliveries. |

| Warehouse Automation | Computer Vision, Robotics, Machine Learning | Higher output. Less labor cost. Better picking exactness. Good use of space. |

| Supplier Risk Management | Natural Language Processing, Machine Learning (Anomaly Detection) | Find supplier issues early. Less supply chain breaks. Better rule following. |

| Quality Control & Machine Care Prediction | Computer Vision, Machine Learning (Anomaly Detection) | Less defects. Lower rework costs. Less machine downtime. More steady product quality. |

Challenges and Thoughts for AI Use

Benefits are strong. But using AI has problems. Knowing these problems helps with success.

Data Quality and Availability

AI needs good data. Many companies struggle with bad data in old systems. Without clean, linked, and enough data, AI models do not work well. Companies must spend on data rules. They must clean data. They must build central data places. This is a must.

Talent Gap and Skill Needs

Using AI needs special skills. These include data science, machine learning work, AI ethics, and knowing supply chain jobs. Not enough skilled people exist worldwide. Companies may need to train current workers. They may need to hire new experts. Or they can work with AI tool providers.

Linking with Old Systems

Many old businesses use complex, outdated ERP and supply chain systems. Linking new AI systems with these old ones can be hard. It can take much time and money. Connectors can help link them. But careful planning is needed.

Moral Concerns and Bias in AI

AI models learn from the data they get. If this data has old biases, the AI can repeat them. It can even make them worse. This leads to unfair or bad choices. Companies must make sure data is varied. They must make sure algorithms are clear. They must test for bias strictly. These are key moral points. Data privacy and security bring big moral and rule problems. This is true when handling private business or customer data.

Cybersecurity Risks

Supply chains get more digital with AI. They link more. They become more open to cyber attacks. Protecting AI models, data paths, and smart automation systems from breaks is a must. Strong cyber defenses must be ready. These include data hiding, access rules, and threat finding systems.

The Future of Supply Chain with AI

Today’s AI uses are just the start. The future brings more linked, smart, and self-run supply chains.

Very Personal Delivery

AI will allow very personal delivery. This means meeting customer wishes for speed, cost, and even green impact. This could mean changing prices for delivery. Or it could mean very specific final delivery methods run by AI.

Self-Run Supply Chain Networks

Think of a supply chain where AI systems make choices alone. These choices cover order placing, production plans, logistics, and stock changes. They need little human help. This self-run supply chain will greatly boost strength and quickness.

Blend with Blockchain and IoT

AI with other new tech will open new ways of doing things.

- Internet of Things (IoT): Live data from IoT sensors gives the exact data AI models need to work well.

- Blockchain: This gives a safe, clear, and fixed record for supply chain deals. AI can use this trusted data. This helps with checks, finding fraud, and seeing everything. The mix makes smart and clear supply networks.

AI-Driven Green Efforts

AI will help make supply chains greener. It plans routes better. It cuts waste through exact predictions and stock control. It finds green ways to source goods. It checks energy use. AI can greatly cut the environmental impact of moving and making goods. This matches world climate goals. It matches growing customer demands for good business ways. AI will help companies not just report on green efforts, but make them better with data choices.

Conclusion

The modern supply chain faces many problems. It changes greatly with AI at its core. We have shown how AI is needed for today’s problems. It gives great skills for demand prediction, stock control, fast logistics, automated warehouses, and strong risk management.

The benefits are clear. Faster work, big cost cuts, better exactness, more strength, and happier customers are some. Challenges exist like data quality and skill gaps. But a smart, step-by-step plan with clear goals can lead to successful AI use.

The future of good business lies in smart operations. Do not let your supply chain fall behind. Find a main problem in your work now. See how a focused AI tool, even a small test, can bring quick value. Start your path to a smarter, stronger supply chain today. The data, the tech, and the need to win all show the time is now.

“